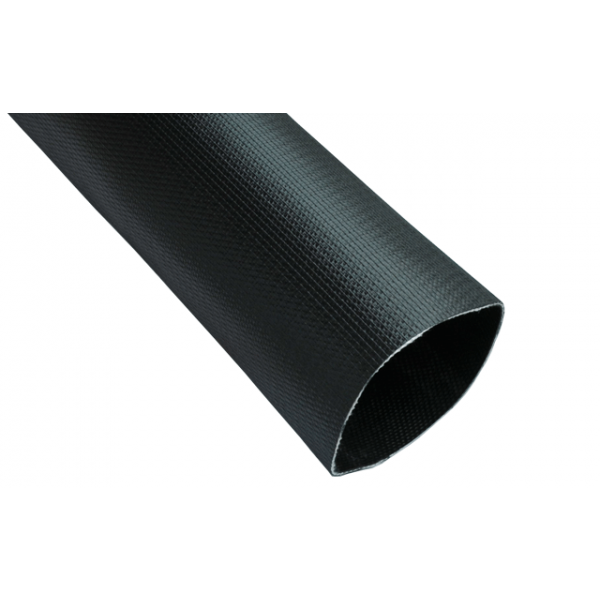

K 450 NBR Lay Flat Hose

Kman 450 is one type of through-the-weave Nitrile Rubber(NBR) covered hose. Kman 450 hoses shall be made from 100% high tenacity synthetic yarn circular woven and completely, totally embedded in the NBR/PVC compound, excellent protected against mechanical damage, forming a single homogenous construction without the use of any glues or adhesives of any type

- Description

Description

Features

- Inner tube: Very smooth with minimum friction loss

- Cover: Ribbed for more abrasion resistance

- Reinforcement: Circular woven polyester jacket

Applications

- Water/Air Transfer

- Mining

- Agriculture & Irrigation

- Marine/Industrial/Construction

- Petroleum/Chemical

- Washdown • Drainage pumps • Water Discharge • Drainage • Irrigation installations • Pumping of sludge and liquid fertilizers • Temporary installations (by-passes) *Recommended for Industrial Water Discharge Solution.

Specifications

| Code | ID | OD | Thickness | Working Pressure | Burst Pressure | Weight | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch | mm | Inch | mm | Bar | PSI | Mpa | Bar | PSI | Mpa | Kg/M | |

| KMAN1.5-10-200 | 1-1/2 | 38 | 42 | 2 | 10 | 150 | 1 | 30 | 450 | 3 | 0.32 |

| KMAN2-10-200 | 2 | 51 | 55.2 | 2.1 | 10 | 150 | 1 | 30 | 450 | 3 | 0.45 |

| KMAN2.5-10-200 | 2-1/2 | 64 | 68.6 | 2.3 | 10 | 150 | 1 | 30 | 450 | 3 | 0.5 |

| KMAN3-10-200 | 3 | 76 | 81 | 2.5 | 10 | 150 | 1 | 30 | 450 | 3 | 0.78 |

| KMAN4-10-200 | 4 | 103 | 108.2 | 2.6 | 10 | 150 | 1 | 30 | 450 | 3 | 1.05 |

| KMAN6-10-200 | 6 | 154 | 161 | 3.5 | 10 | 150 | 1 | 30 | 450 | 3 | 2.15 |

| KMAN8-10-200 | 8 | 204 | 211 | 3.5 | 10 | 150 | 1 | 30 | 450 | 3 | 2.8 |

| KMAN10-10-200 | 10 | 254 | 262.6 | 4.3 | 10 | 150 | 1 | 30 | 450 | 3 | 4.2 |

| KMAN12-10-200 | 12 | 305 | 314 | 4.5 | 10 | 150 | 1 | 30 | 450 | 3 | 5.4 |

*Construction: Tube-NBR; Reinforcement-Polyester; Cover-NBR.

*Flexible in all weather conditions from -20 deg C to 80 deg C.(-4 deg F to 167 deg F).

*Standard lengths: 200m (660ft) . Longer or shorter lengths available on request.

*Strand color: Black ribbed. Other colors are available.

*Similar products: Oroflex 10 of Tipsa, Superflow of Key, etc

Lining Properties

a. Ultimate Tensile Strength:

Tensile strength of the lining and cover shall not be less than 1500 psi (10,500 kpa ).

b. Ultimate Elongation:

400% minimum.

c. Accelerated Aging Test

The tensile strength and ultimate elongation of the vulcanized rubber compound which has been subjected to the action of oxygen at a pressure of 300 psi +/- 10 psi , (2100kpa +/- 70kpa) and temperature of 70 degrees centigrade +/-1 degree centigrade (158 F +/- 18 F ) for a period of 96 hours shall be , greater than 60% of the original properties stated.

Elongation at WP:<1.5%

Expansion at WP:<6%

Abrasion:6000 DIN cycles